Description

Automatic high bay racking – Saving time and money

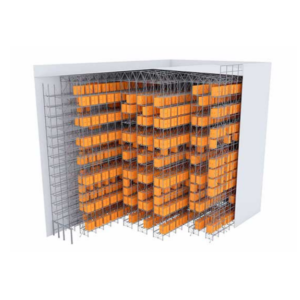

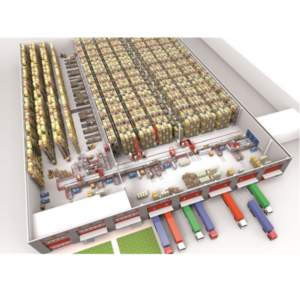

For certain types of Automatic high bay racking is the optimal solution. Apart from the obvious advantage that the crane racking system maximises storage by height, the manual handling of goods is also significantly reduced. The workplace safety for the warehouse personnel is increased as much of the labour is automated. The automated handling also contributes to better inventory monitoring and faster flow of goods.

Adaptable storage with endless possibilities

The flexible crane storage system has many different configuration possibilities. It doesn’t really matter how the layout of the warehouse is, the crane storage system is easy to adapt to the space and to the needs for capacity and functionality. The system is suitable for most types of pallets and load carriers, making it compatible with other storage systems.

Lower cost – full control

A crane storage system can be used either as a supplement, for example for goods that can be picked up in advance for later delivery, or as the main warehouse system with the possibility of loading and unloading. With this type of automated storage system, not only inventory management costs are lowered, but it also gives complete control over inventory, delivery control and storage time – all contributing to a significantly greater delivery accuracy.

For a safe workplace

As you probably know, a qualified inspector should annually inspect all storage systems. We have over the years built and refined a good relationship with inspection companies. A contact we are happy to share with you. When the inspection is completed you can send the report to us and we will ensure that maintenance is carried out in a safe and adequate manner.

Click here to learn more!

Comments are closed here.