Description

Autonomous mobile robots software is a leading Software to Enable Robots to Navigate Autonomously. Autonomous mobile robots software enables robots to localize and navigate autonomously can be easily integrated in any mobile robot.

Features

- Navigation – smooth and quick obstacle avoidance combined with automatic re-routing.

- Hybrid Fleets – combination of various models and different types of shuttles from multiple vendors possible within one fleet

- Hardware Integration – large existing hardware database and easy integration of new models using a standard hardware abstraction layer.

- Deployment – quick and easy deployment of FMS and shuttles using existing infrastructure

- Customisations – apps ready to add process, order and floor management tools.

- Optimisations – ongoing optimisation of navigation software, kinematics and learning capabilites over the cloud

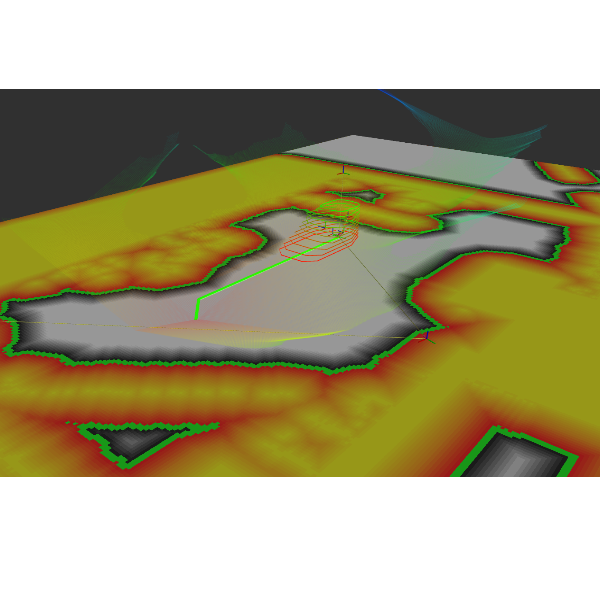

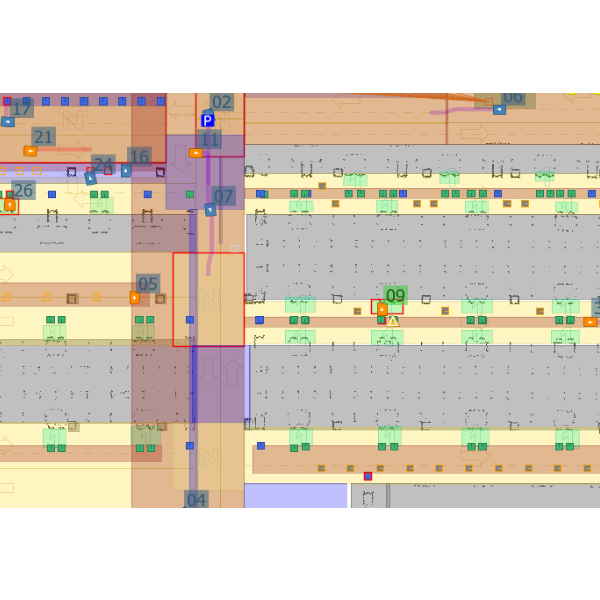

- Digital Twins – the digital twin serves as advanced planning and verification tool for the complete project life cycle – planning, operation, support and process adaption

- Services – 3rd level support, Training and Consulting

Benefits

- Flexibility – AMRs navigate freely and move around obstacles in real-time

- Scalability – additional robots can be added effortlessly to existing fleet upon request

- Retrofitting – retrofittable and easy to implement: No constructional changes are necessary – instant deployment

- Safety – safety certifications allow mixed operations with humans and machines next to manual processes

Examples of use cases

Efficiency of warehouse logistics

- Complex setting with 50 different stations.

- Long distance transports of individual pallets inside the warehouse.

- Quick implementation of warehouse automation to cope with the fast-changing industry needs.

- Warehouse parts with normal temperature (shelf stable foods) and cooler part (cold storage foods)

- 40 autonomous pallet carries pass 1,000km per day.

- They manage up to 500 orders per hour in peak periods.

- No single point of failure.

Flexibility for unpredictable E-commerce

- High return rates in the fashion industry.

- Manual handling of goods at the workstations needed.

- Seasonal workload and varying amount of goods.

- Varying types of goods

- Eliminated the need for conveyor link to every workstation which helped workflow flexibility, accessibility and cost optimization.

- 600 transports per hour – to and from workstations and shelves.

- Workstations did not require integration with the robots and the software leading to simpler and cheaper deployment

Production

- Securing the investment when the production plant is abandoned.

- Flexibility in case of reorganization and extensibility (scalability).

- Skilled workers can focus on value-adding activities.

- Cheaper than conveyer with high initial investment need.

- Protect workers’ health – having machines do the hard, physical work.

- Increased hygiene from reduced movement of humans.

Click here to learn more!

Comments are closed here.