Description

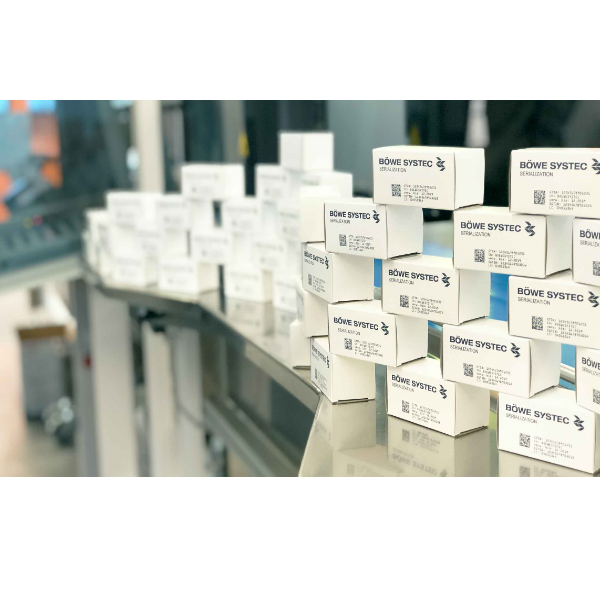

According to the UN’s World Health Organization (WHO), a tenth of medicines worldwide are falsified and in Europe the figure is one in a hundred. The WHO estimates that around one million people die every year as a result of falsified medicines. This needs to be stopped using BÖWE SYSTEC Serialization & Decommisioning, and reliable serialization and marking systems for pharmaceutical producers and logistics companies should put an end to the world’s life-threatening trade in falsified medicines. The EU Falsified Medicines Directive 2011/62/EU (FMD for short) made serialization mandatory on February 2, 2019. The FMD poses considerable technical and commercial challenges for pharmaceutical logistics but with BÖWE SYSTEC’s serialization module you are well equipped and can start right away.

Advantages

- All in one: serialization, decommissioning, control

- Wide spectrum of formats

- Audit-proof data processing

- Stand-alone solution

- Intuitive operation & scalable software

- All from a single source

Technical information

- Formats – 25 x 25 x 40 – 250 x 250 x 400 mm

- Security – Maximum Integrity & Auditable Data Processing

- Sensor Technology – Reliable Measuring & Product-Based Tracking

- Modularity – Modular & Ergonomic Design

- Modular Software Design – 3 Editions

- Operation – Easy, Intuitive Operation

Serialization and decommissioning in one system

BÖWE SYSTEC is a specialist in Track & Trace solutions and as the sole supplier in the market it has developed a solution specifically for the pharmaceutical industry that combines all relevant functions in one system:

- Automatic serialization and imprinting of the data code matrix (GTIN, NTIN, PPN, expiry date as well as batch number) on unprinted folding boxes.

- Verification of already printed packaging.

- Automatic decommissioning.

- Target/actual comparison of batch (total control).

- Sampling and print quality checks using a hand-held scanner

All kinds of formats

Individual speed adjustment (max. 25 m/min) allows the system to process every conceivable form of packaging reliably and, above all, securely—right from the smallest 25 x 25 x 40 mm folding box up to oversize 250 x 250 x 400 mm medicine packages. A further feature of our unique solution is that job changeovers when switching formats are simple and the changeover times correspondingly short.

Stand-alone modular solution

The serialization module does not just offer reliable implementation of the pharmaceutical directives in a single system. Ultra-flexible and ergonomic, the highly adjustable system can be easily detached at any time and repositioned or integrated into other systems.

Intuitive software means short training times

The BÖWE SYSTEC serialization module offers intuitive operation that combines the highest possible flexibility with the simplest of handling. Its unique advantage is that product handling, coding and camera-based inspection are operated via just one software interface. The open interface software can be tailored to individual customer requirements and for single or multiple machines, as required. Very much in the spirit of the industry of the future, even systems in geographically scattered locations can be networked with each other through our corporate software.

Consistently thought out reliability

The reliability of a system is clearly a top priority when providing protection against falsified medicines. The BÖWE SYSTEC serialization module consistently implements Track & Trace and guarantees comprehensive serialization right up to the final stage in the process. The very latest reading technology based on the certified topSenso Eagle camera (Area Scan) and our own parameterization and verification software is used to ensure seamless item tracking throughout the production process. BÖWE SYSTEC Track & Trace software guarantees end-to-end serialization with 100 % security and traceability along the entire process chain through open interfaces that are tailored to your company. The software is available in three levels: line, site or corporate. It communicates with all of your company’s production sites in real time to ensure that a serial number will never be issued more than once anywhere in the world. Auditable data processing goes without saying and a smart spacing system also prevents multiple item selection. Different access rights can be simultaneously set for the software so that operators with different privileges can be granted different rights.

With billions of error-free scans we have been satisfying the exacting security and quality standards of banks, insurance companies and public authorities for decades. Take advantage of our 30 years of Track & Trace know-how.

The BÖWE SYSTEC solution offers you a flexible and modular Track & Trace system that is perfectly tailored to the needs of pharmaceutical logistics and that satisfies the current EU directives. With our serialization module you will be in the best possible position to implement future global Track & Trace requirements.

Click here to learn more!

Click here to find your BÖWE SYSTEC partner

Comments are closed here.