Description

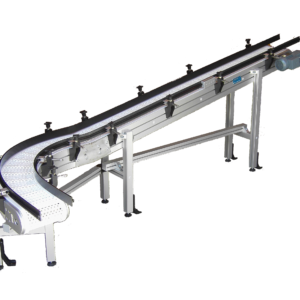

Pieri designs and builds wrapping lines; our ongoing research and development has enabled us to develop high-performance solutions which meet the needs of modern industrial systems. We also supply reliable and technologically advanced conveying systems. Our machines are practical, configurable and versatile, all qualities they need to survive on a competitive and continually evolving market.

Our range of products include:

- MOTORIZED ROLLER CONVEYORS – MOTORIZED CHAINS CONVEYORS,

- TURNTABLE STATION The turntable station enables the pallets to change direction. This device consists of a roller conveyor or chain conveyor able to rotate on its axis. The turntable station, rotating on its axis, permits to change the direction without changing the feed front side, and thus the type of conveyor.

- ROLLER/CHAIN EXCHANGER The roller/chain exchanger enables the pallets to change direction. It combines the characteristics of the roller and chain conveyors. The exchanger permits changing direction and the feed front side of the pallet. It is the chain conveyor’s ability to raise or lower its conveying surface. The roller/chain exchanger needs to be connected in one side of roller conveyors and in the other side of chain conveyors.

- SHUTTLE The shuttle is a device for moving pallets. This type of conveyor consists of a roller conveyor, a chain conveyor, a rotating station or, in any event, a wheeled conveyor running on rails.

- EMPTY PALLET DISPENSER The empty pallet storage satisfies the requirements of depositing empty pallets on one side and production line feeding pallets on the other. The operator deposits the empty pallets in the storage system and, if necessary, the automatic device equipped with conveyor distributes the pallet on the line to receive the product. Capacity up to 15 pallets.

Comments are closed here.