Description

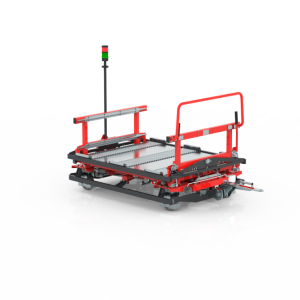

E-LINER

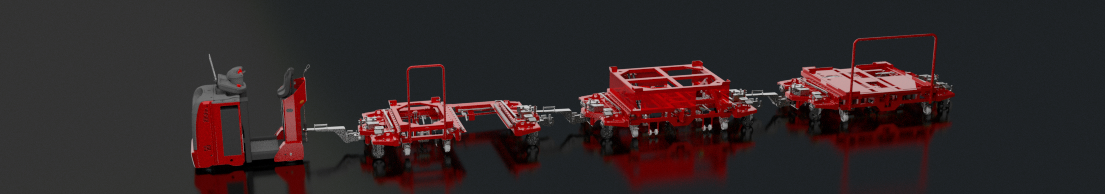

E-Liner production transport is the widest spreaded over the World and innovative lean solution dedicated to internal logistics. Its characteristics are: wide scope of use, great traction abilities, cooperation with different kinds of trolleys and containers and very high level of both quality and user safety. The system consists of tugger train trolleys, transport platforms and specially designed turntables which lower the time of containers’ exchange on the production line.

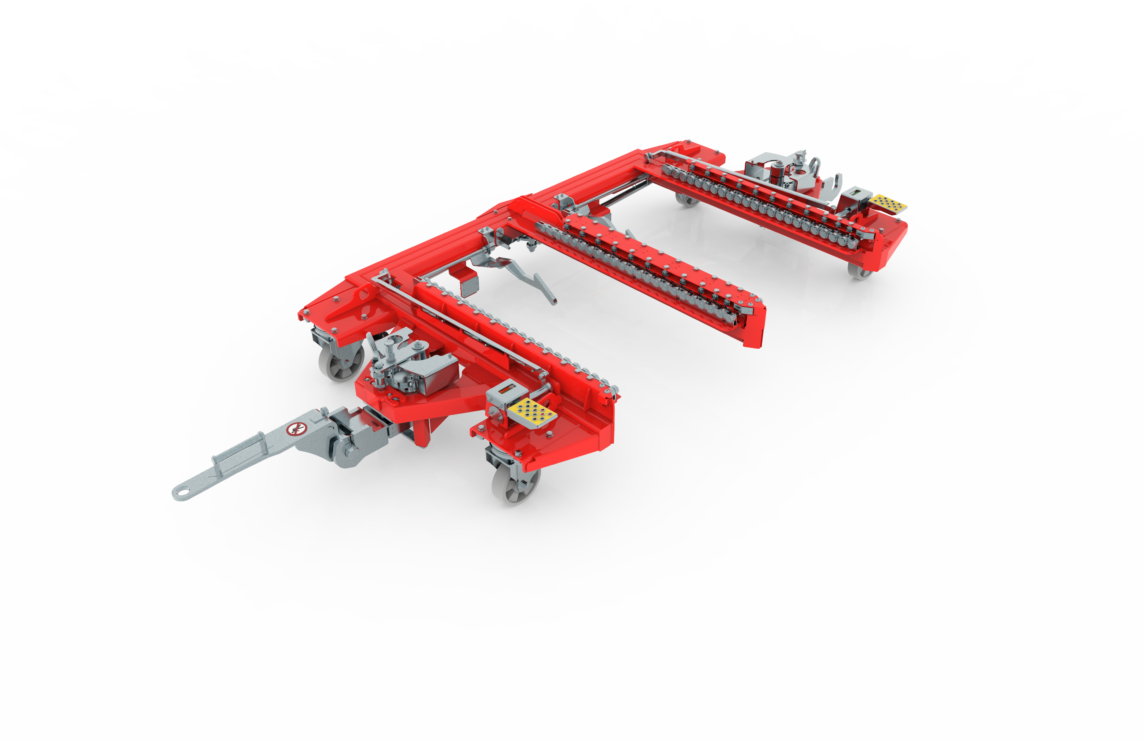

STANDARD E-LINER PLATFORM

– Dimensions: 2990 x 1290 x 375 [mm] (l/w/h)

– Dimension of containers: 2 x 1000×600, 2 x 800×600, 1200×1000, 1200×800, 1600×1200 [mm]

– Max load of platform: up to 1000 [kg]

– Max load of tugger train: do 5000 [kg]

– Platform’s net weight: 330 [kg]

– Max speed: 10 [km/h]

– Max lenght of train: 6 platforms

– Turning radius: 3 [m]

– Turning circle diameter: 6 [m]

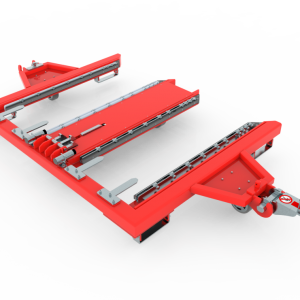

SMALL E-LINER PLATFORM

– Dimensions: 2990 x 1090 x 375 [mm] (l/w/h)

– Dimension of containers: 2 x 1000×600, 2 x 800×600, 1200×1000, 1200×800 [mm]

– Max load of platform: 1000 [kg]

– Max load of tugger train: 5000 [kg]

– Platform’s net weight: 315 [kg]

– Max speed: 10 [km/h]

– Max lenght of train: 6 platforms

– Turning radius: 3 [m]

– Turning circle diameter: 6 [m]

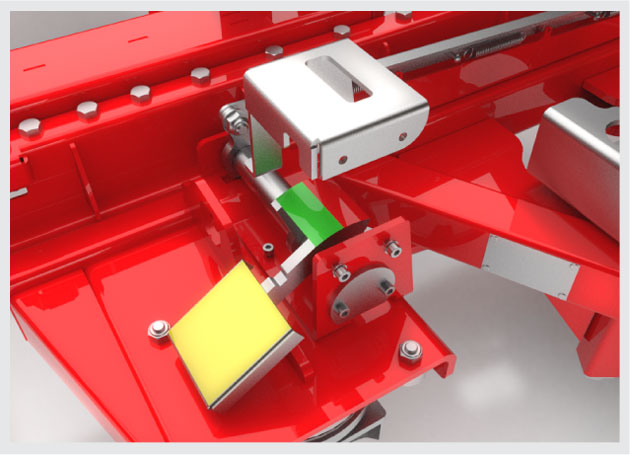

FULLY MECHANICAL SYSTEM

Milk run systems supposed to be a lean manufacturing solution and so we have designed our E-Liner production transport. Our platforms and carts do not require any additional power supply. All the systems used are 100% mechanical therefore you lean your production two times – first by implementing the tugger train solution and second time when u have no cost of certification, servicing and power usage.

PATENT

The uniqueness of our intralogistic system confirm not only the above mentioned features but also the patent protection.

Comments are closed here.