Description

For newcomers, a short definition before we start with the details. Pick-by-Light is a fast and error-free picking method for undocumented picking, sequencing and production.

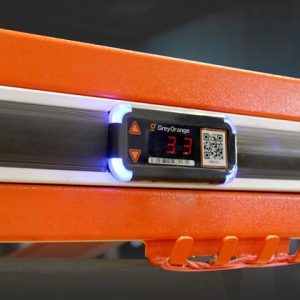

After the data collection and activation of the picking order, the process begins. The matching LEDs light up directly on the items. This allows the picker to quickly find his withdrawals on the shelf. The quantity display shows the quantity to him. He can confirm the activity directly at the trade advertisement with the receipt button. In the case of missing quantities, the number of pieces on the quantity display can be corrected directly via plus/minus buttons.

Performance and quality

Performance and quality are opposite parameters. As a result, the more performance is expected, the less quality the picker can provide. Increasing performance and quality at the same time is not easy with any of the picking methods.

As a leading picking procedure, Pick-by-Light is an excellent example of how performance and quality can clearly increase rapidly.

The performance increases up to 40%. The targeted support of the access to the storage compartment also increases the quality by more than 15%. This minimizes pick errors. When using sensors, the quality is added by about 10%.

When planning a non-evidence picking, it is essential to consider the economics. The Pick-by-Light requires a relatively large amount of hardware, which does not make the procurement of the equipment particularly inexpensive.

An ROI calculation must show whether the investment is profitable. Get in touch with us. We will help you to perform the calculations.

If the demand for performance is not particularly high and the storage areas are large, we also supply other technologies for the picking processes, such as Pick-by-Scan , Pick-by-Watch , Pick-by-Voice Etc.

Where is Pick-by-Light Used?

The following industries have been successfully using our Pick-by-Light :

- eCommerce: Picking and replenishment in the mail order warehouse

- Automotive: Picking and sequencing of shopping baskets and JIT containers for assembly lines

- Production: Assembly stations, set-making and machine assembly

The undocumented picking method is very versatile and is intended to support the picker and avoid picking errors. The modules themselves serve only as output and input devices. The entire logic of the control, as well as the process, is found in our LUCA-Server Instead of.

How is a Pick-by-Light Built?

The Pick-by-Light is highly modular and very flexible. All available trade advertisements can be shared. Our software takes on the main role of the control LUCA-Server .

In the server, we not only implement the communication to the specialist advertisements, but also control the entire process logic, as well as the connection to the warehouse management system. The orders are transferred as electronic picklists. Additional components (e.g. scanners, RFID readers, machines, conveyor technology, etc.) are also LUCA-Server Managed.

Here are the main components:

- LUCA-Server (customer-facing Windows virtual server)

- Controller (multiple BUS systems)

- Mounting rails with integrated BUS system

- Specialist displays with signal lamp (LED’s), quantity display and a receipt button

Comments are closed here.