Description

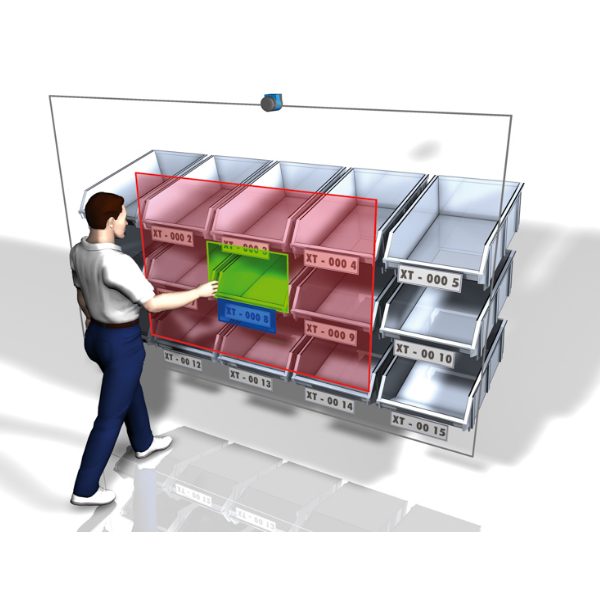

Pick Radar® monitoring of access to the storage compartments is realized with a rotating laser (Class1). The system ensures the quality of picking or sorting and helps with automatic receipts of withdrawals. In the event of an access error, the LUCA-Server an alarm is triggered and logged.

The Pick Radar® Principle

Actually, Pick Radar® no picking systemon its own . This is about access control. A laser head from the Pick Radar (no radar wave) rotates 50 times per second and measures the distance and angle to the objects. The measurement data is displayed directly on the LUCA-Server or LUCA device gateway. The work surface is defined by a configuration during commissioning. Individual functional surfaces are configured on the desktop. In the process on the LUCA-Server (picking or sorting) the corresponding functional surfaces are activated. When access is made to one of the active functional surfaces, the process is notified and a response is triggered.

The following functional areas are defined and freely configured (colors from the graphic):

- Access (GREEN)

- Forbidden (ROT)

- Acknowledgment (BLUE)

- Work surface (the frame)

The maximum size of the work surface is approx. 20 meters

Use of surveillance

The pick radar® is usually used as a monitoring system in combination with other picking systems,such as pick-by-point®, Pick-by-Light Or Pick-by-Voice Used. In the case of Automotiv (always 1 piece), the automatic acknowledgement of the picking is triggered directly with the access. Incorrect access to the storage compartments generates an alarm or light signal. No employee data is collected or logged.

Click here to learn more!

Comments are closed here.