Description

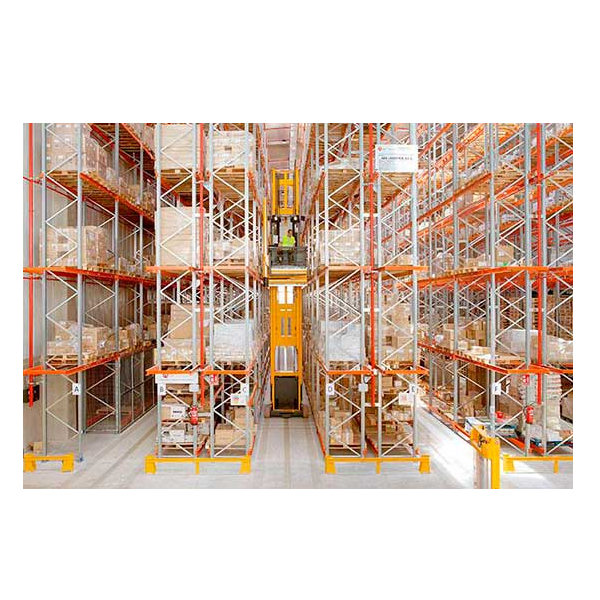

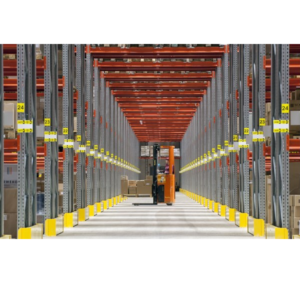

The Adjustable Pallet Racking system (APR) is designed to store pallets in a mechanical and functional way using forklifts. These forklifts access goods through aisles parallel to the racks. The use of Adjustable Pallet Racking system (APR) is a logistical solution which can be adapted to the dimensions of the unit loads and the forklifts.

Efficient, resistant, easy-to-assemble, and with simple load level regulation, this system adapts to any type of product, both by weight and by volume. These systems can be adapted for picking.

Depending on the handling equipment SIN, two types of system can be offered:

· APR system for Class 400 (Conventional Racking System)

· APR system for Class 300 or VNA Pallet Racking for Very Narrow Aisle forklift trucks

The APR storage system is dimensioned according to both the European regulations in force and FEM (European Materials Handling Federation) recommendations.

Advantages of the Adjustable Pallet Racking system (APR):

- Adapts to any type of unit load and forklift.

- Allows direct and immediate access to goods.

- Quick and efficient assembly, disassembly and replacement of parts.

- Quick placement and access to every pallet directly and immediately.

- Strict control of stored SKUs; each storage location matches a unit load.

- Time and effort saving when handling goods, achieving high stock rotation.

- Ability to meet changing needs.

- With a variety of available accessories and configurations, the rack can be tailored to any load weight or volume.

- Maximization of space by easily and quickly adjusting beam levels to meet any required volume.

- Easy-to-assemble modular structure. The assembly design of the different structural elements makes disassembly and re-installation easy, as well as any racking reconfiguration and/ or enlargements in case of new storage needs.

- Increased safety factor thanks to the accessories used.

- The AR-range uprights and frames are pre-galvanised and have an innovative traceability system.

Main applications of Adjustable Pallet Racking:

Since it is the most common and conventional storage system it is the most widely used, and thanks to its adaptability and versatility its application is useful for diverse storage needs.

However, we specifically recommend using an adjustable pallet racking system in the following situations:

- Storage of unit loads with a wide variety of references.

- Storage with need for direct access to each unit load.

- High turnover storage with non-homogeneous products.

- Storage of non-standard unit loads that require specific accessories, such as coils, drums and containers.

- Warehouses that require a combination of pallet and picking racks.

Quality and security

Adjustable pallet racking solutions comply with the strictest European safety standards, and also come with AR Racking’s quality and innovation guarantee.

5-year quality guarantee

The reliability of our adjustable pallet racking solutions means we are able to offer 5-year quality guarantees against all types of manufacturing or hidden defects in the components of the main structure of our racking solutions.

Pioneering component traceability system

Since 2016, our adjustable pallet racking components have included a component traceability system.

With this system, the various above-mentioned elements have an identifying mark, which means being able to trace and document each component from origin without needing to have the package label, and therefore, knowing which piece it is, its design and what raw material has been used in its manufacture.

100% automated production

Our industrial racking production process is fully automated: it incorporates state-of-the-art profiling machines with a continuous cutting process and laser measurement control, welding centres, painting and packaging processes, all automated, which guarantee the highest quality parameters.

Designs in R&D&I Centre

The structures of our adjustable pallet racking systems are designed in our exclusive R&D&I technology centre and supported by the advanced engineering project development area, helping to provide a suitable response to the most demanding logistics requirements.

Tests at Research and Testing Laboratory

With the creation of our Research and Testing Laboratory in collaboration with the University of Mondragón, our technical area continuously tests and analyses products and materials to improve our adjustable pallet racking systems; it simulates, calculates and researches (with specialist software) the efficacy of the geometries, and makes full structural calculations on the behaviour of the systems already installed in different situations.

Adjustable Pallet Racking quality certificates:

- ISO 9001: 2008

- ISO 18001: 2004

- OSHAS 18001: 2007

- Welding certificate: UNE EN ISO 3834-2: 2006

- Galvanized steel corrosion resistance certificate: UNE EN ISO 14713-1

- Galvanized steel reaction to fire: EN 13501-1: 2007

- Adjustable Pallet Racking Quality Certificate

- EN 15512

- EN 15620

- EN 15629

- EN 15635

- FEM 10208

Click here to learn more!

Comments are closed here.