Description

The model AVR 400 FLEXA TS is a fully automatic rotating ring wrapping machine with integrated top sheet applicator. The TS integrated device covers the top of the palletised load with a polyethylene film and is ideal for protecting it against water and dust.

Technical Data

| STANDARD FEATURES | AVR 400 FLEXA | AVR 400 FLEXA TS |

| Productivity | ||

| Standard Cycle | Up to 90 p/h | Up to 90 p/h |

| Waterproof cycle | NA | Up to 75 p/h |

| Rotation speed | Up to 50 rpm | Up to 50 rpm |

| Pallet dimensions* | ||

| Min. LxW | 800×600 mm | 800×600 mm |

| Max. LxW | 1000×1200 mm | 800×1200 mm |

| Min. load height | 500 mm | 500 mm |

| Max. load height | 2100 mm | 2100 mm |

*Available for non-standard pallet and load dimensions

Optional components

- Top press plate

The top press plate exerts pressure on the palletised load to keep it stable during wrapping.

Specially designed for wrapping machine loads, it is available in a pneumatic or electromechanical pantograph version. - Pallet lifter

This device lifts the pallet during wrapping cycle, in this way the film covers both: the load and part or all of the wooden pallet. - Roping device

As the name suggests, the roping system on the carriage reduces the width of the film until a rope is created, increasing load stability and securing the product to the pallet. - In-line top sheet applicator STF203

This automatic device, positioned before the wrapping machine, covers the top of the palletised load with a polyethylene film, protecting it from dust. The film is cold cut by a pneumatically powered blade. The amount of film to place on the load is automatically calculated by a photocell, ensuring optimal consumption. - Electronic pre-stretch carriage with two motors – mod. PEM-Duo

Electronic spool carriage with variable pre-stretching driven by two motors controlled by an inverter.

The pre-stretch percentage can be set from the electrical control panel (minimum 120% – maximum 450%) by adjusting the speeds of the motors installed on the carriage separately. This takes full advantage of the characteristics of the film, with a significant reduction in the amount used.

It is also possible to set different pre-stretch percentages for each programme and wrapping cycle, ensuring maximum stability of the palletised load.

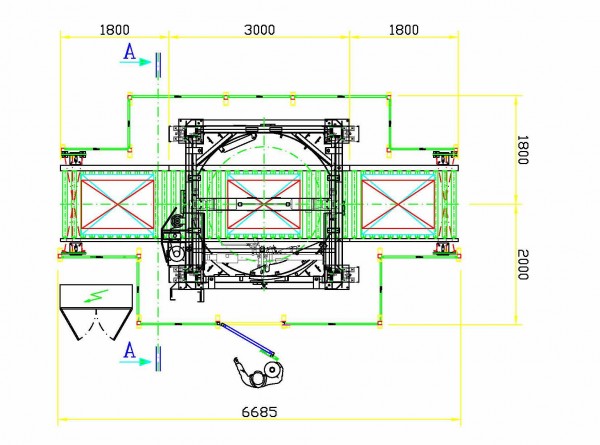

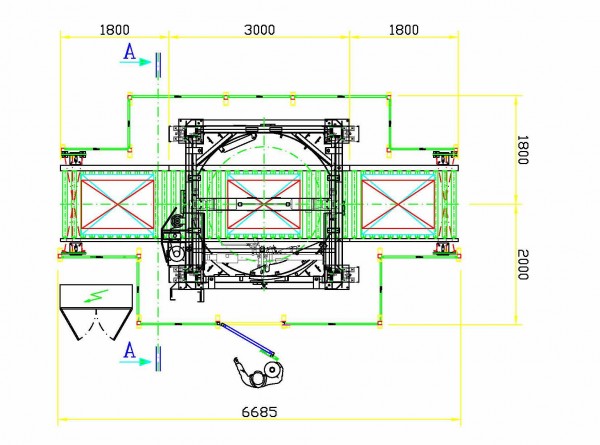

Layout

Comments are closed here.