Description

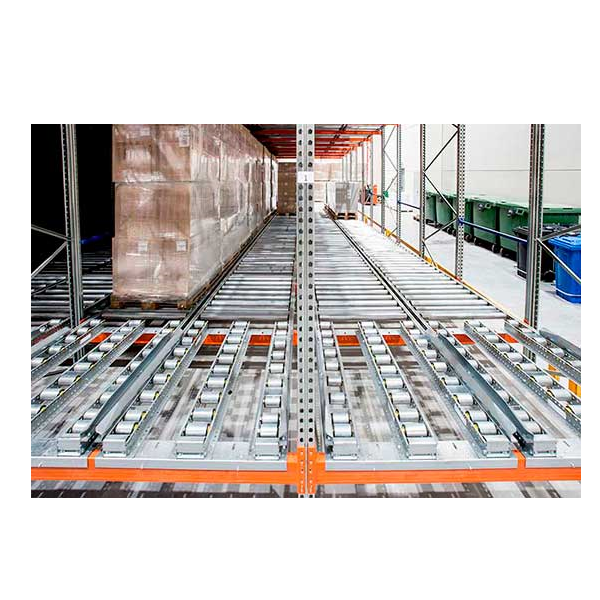

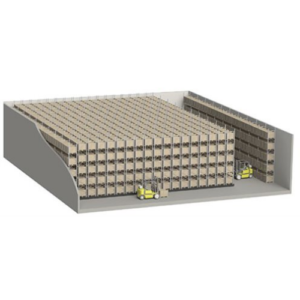

Live Pallet Racking (FIFO) is ideal for warehouses where stock turnover control and space saving are critical. The Live Pallet Racking (FIFO) compact structure uses slightly inclined roller beds on each level to allow unit loads to be moved more easily.

AR Racking offers two types of live pallet racks:

This system uses the FIFO (first in, first out) method, where the loading area is at the opposite end of the unloading area and the goods are transported through this space thanks to the roller beds that form a rail with an incline.

As a complement to Live Pallet Racking FIFO there is also Push-Back Racking LIFO which uses the LIFO system (last in, first out) and therefore has a single loading and unloading point; goods are stored by pushing the previous ones towards the back.

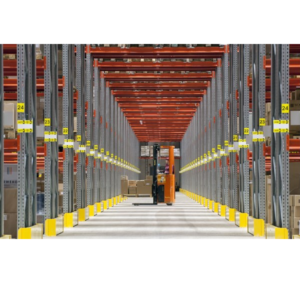

Live Pallet Racking is the perfect high-density storage system for homogeneous pallets.

Advantages

The advantages of live pallet racking FIFO are their compaction, time savings and good stock management.

- Reduced loading and unloading times.

- Increased storage capacity in a warehouse with adjustable pallet racking.

- Enabling of loading and unloading aisles reduces risks for the operator.

- Live pallet racking system can be automated.

- Optimal use of space. High-density storage system, so more storage capacity in the same space

- Ideal product rotation: Perfect for FIFO systems (first-in, first-out).

- Fast, simple removal. Ideal positioning of the products reduces load manoeuvre and extraction times.

- No traffic interference. The forklift trucks insert and remove load units in different aisles since the loading and unloading aisles are separate.

- Adaptable to any space, and to any weight or size of the merchandise to be stored.

- Extremely safe. The Live pallet racking structure is fitted with a control and braking system to minimise any risks: brake rollers, pallet centring or retainer system, and pallet stops.

- Improved stock control since each loading aisle has a single product reference.

- Dynamic pallet system is compatible with other automatic and conventional storage systems.

- Allows you to continue to use the same type of forklift trucks used in adjustable pallet racking warehouses.

- Reduced operating costs thanks to excellent use of space.

- The uprights and frames of the AR range are pre-galvanised.

Main applications of Mobile Pallet Racking

Live Pallet Racking systems significantly optimise the space available in the warehouse, but live pallet racking FIFO in particular, due to its stock management method, is especially recommended in the following circumstances:

- Storage of goods with an expiration or best-before date, due to its excellent stock management. The first products to enter will be the first to leave the warehouse.

- Warehouses for companies in the Food, Medicines, Cosmetics sector or sectors whose products become obsolete or “go out of style” very quickly.

- Storage in intermediate or transition zones between several areas within the same warehouse, to facilitate the fast movement of the unit loads.

- Storage in order, waiting or dispatch areas in the warehouse; live pallet racking FIFO facilitates the flow of goods.

- Possibility of installation in warehouses with cold rooms or freezing chambers.

Quality and security

Live pallet racking FIFO systems comply with the strictest European safety standards, and also come with AR Racking’s quality guarantee.

100% automated production

The production process of the basic components of our live pallet racking is fully automated in our factory: it incorporates state-of-the-art profiling machines with a continuous cutting process and laser measurement control, welding centres and automated painting and packaging processes, which guarantee the highest quality parameters.

Designs in R&D&I Centre

Our live pallet racking systems are designed and calculated in our R&D&I technology centre where we have an expert team which allows us to tackle projects with the most complex logistics requirements.

Tests at Research and Testing Laboratory

The Research and Testing Laboratory developed in collaboration with the University of Mondragón provides our product area with the appropriate tools for the testing and analysis of our racking systems; it simulates, calculates and researches the efficacy of the geometries, and makes full structural calculations on the behaviour of systems already installed.

5-year quality guarantee

The quality reliability of our live pallet racking solutions means we are able to offer 5-year guarantees of excellence against all types of manufacturing or hidden defects in the components of the main structure of our racking solutions.

Innovative component traceability system

The uprights and beams of our pallet racking systems include an innovative traceability system in the sector.

Thanks to this system, our storage system components have an identifying mark, which means that each upright and beam can be traced and documented from origin, and that information is therefore available on which component it is, its design and the raw material used in its manufacture.

Quality certificates of the Live Pallet Racking system:

- ISO 9001: 2008

- ISO 18001: 2004

- OSHAS 18001: 2007

- Welding certificate: UNE EN ISO 3834-2: 2006

- Galvanized steel corrosion resistance certificate: UNE EN ISO 14713-1

- Galvanized steel reaction to fire: EN 13501-1: 2007

Click here to learn more!

Comments are closed here.