Description

The financial success of your company is heavily dependent on reliable intralogistics. Challenges quickly emerge, such as how to design material flow systems from the ground up or how to account for the interaction between production, supply chain transport, and storage areas. The implementation of timely and reliable decisions is crucial.

Material flow planning software simplify your material management

Divergent transport flows and non-transparent material flows are frequently a challenge for manufacturing companies. Additional challenges include long processing times, high production costs, and a lack of transparency and flexibility in both value stream analysis and production planning. The best strategy: material flow simulation software.

We know this process is not always easy to implement! Our ipolog software supports you every step of the way!

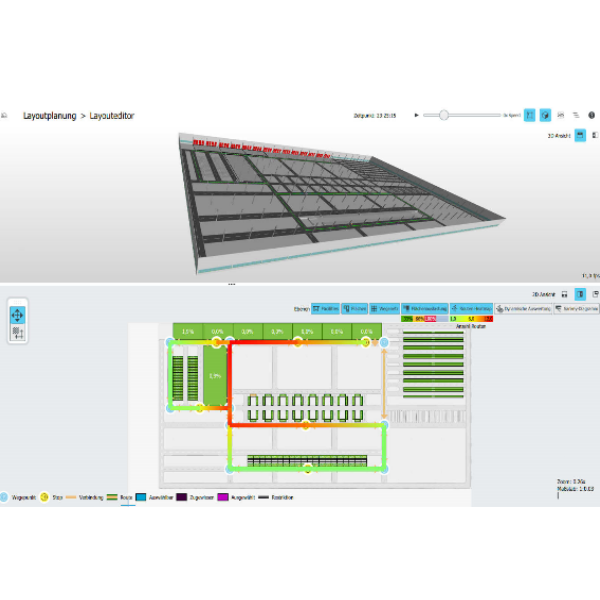

ipolog helps you efficiently plan your material flow layout. Make bottlenecks and interrelationships more transparent to ensure an optimal supply for your production or assembly. We provide you with digital simulation solutions for material flow so that you can utilize your tugger trains, forklifts, AGVs, and staff as efficiently as possible.

Don’t have forklifts and AGVS, but would still like to improve your tugger train system? Not sure how? Then read here how easy tugger train optimization can be: tugger train planning with ipolog.

Why is the ideal material flow management so important for your company?

Here are a few benefits of implementing digitally supported material flow planning:

Digital Verification of Important Concepts

You need to ensure a continuous supply of materials in high volumes and with a large number of variants. A digitally verified supply is the best strategy.

Comprehensive Planning Using Algorithms

Your production is characterized by high complexity. Software-supported planning using algorithms takes some of the weight off your shoulders.

Reduced Planning Effort

The planning time required for material flow is high – especially for tugger trains. ipolog software saves you a lot of time and frustration.

Mastering of Complexity

Due to the complexity of increasingly individualized products, there’s no room for safety stock on the assembly line. That means your supply must be precisely timed to function correctly.

Advantages of software-supported material flow planning

Through value stream analysis or a digitalized material flow you can achieve transparent, automated tugger train planning with automatic results such as tugger train demand, employee demand, tours per day, total distance and process times. Your direct transports are also analyzed and optimized – regardless of whether they are forklifts or an AGV fleet system.

In addition, a 3D simulation for visualization and validation enables safe planning and operations. A 2D representation of the material flow using a Sankey diagram and heat map also help with system optimization.

Use our ipolog software for your material flow

Advantages of planning in ipolog:

Automated Transport Planning

ipolog enables you to plan tugger trains and other modes of transport automatically.

Line-Back Calculation

What has to happen during the day to complete the production program? ipolog tells you!

Recording of Process Times

Process times can be stored in standard logistics processes for thousands of parts at once.

Automatic Analysis

You can look forward to an automated evaluation of resource requirements and staffing requirements (dynamic, no static Excel daily average).

Would you like to benefit from the advantages of software-supported material flow planning? Then put our ipolog software to the test.

Comments are closed here.