Description

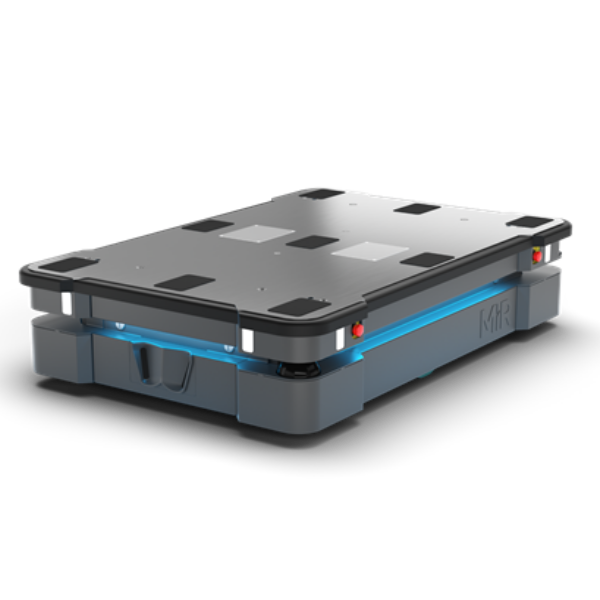

The MiR600 is a stronger and safer AMR. The MiR600 is compliant with the highest available robot standards making it superior to other AMRs on the market.

Safe and efficient maneuvering

The collaborative MiR600 safely maneuvers around people and physical obstacles. With its advanced technology and sophisticated software, the robot autonomously navigates to find the most efficient path to its destination. When it meets obstacles, it will automatically re-route to avoid costly lags in logistics processes.

MiR600 is equipped with the latest laser-scanning technology that delivers a 360-degree visual for optimal safety. 3D cameras have a range of 30-2,000 mm above floor level to detect pallets.

Dimensions for each pallet lift

- Length – 1 350 mm | 53.1 in

- Width – 910 mm | 35.8 in

- Height – 322 mm | 12.7 in

- Ground clearance – 25 – 27 mm | 1.0 – 1.1 in

- Weight (without battery or payload) – 229 kg | 504.9 lbs

- Load surface – 1 304 x 864 mm | 51.3 x 34 in

- Wheel diameter (drive wheel) – 200 mm | 7.9 in

- Wheel diameter (caster wheel) – 100 mm | 3.9 in

Payload

- Maximum payload – 600 kg | 1 322.8 lbs

- Acceleration limits with payload – 0.37 m/s2. | 1,21 fps2

- Footprint of payload – Robot footprint. Contact MiR if a bigger payload footprint is required.

- Payload placement – Place center of mass according to directions in the user guide

- Maximum lifting capacity with a MiR EU-/US-/Shelf-lift installed – 500 kg | 1 322.7 lbs

Speed and performance

- Maximum speed (with maximum payload on a flat surface) – 2 m/s | 6.6 fps

- Maximum acceleration – 0.41 m/s2 (no payload), 0.37 m/s2 (maximum payload)

Pallets

- EUR-pallets dimensions – 1200 x 800 mm / 47.2 x 31.5 in

- Pallet production specifications – EN 13698-1

Click here to learn more about MiR EU Pallet Lift 600 TM!

Click here to find your distributor!

Comments are closed here.