Description

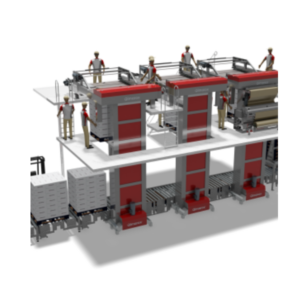

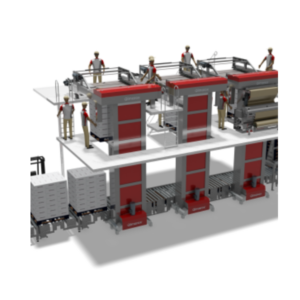

Palletizer ILERPAL C. High level bag’s palletizer, lateral bag pushing, layer compacting and mobile platform

BENEFITS

- Perfect shape of the end pallet

- Between 1 and 1’5 kW of energy saving in the elevation platform, 20 % to 25% consumption reduction on the gearboxes and longer lasting of the mechanical elements due to the use of low friction surfaces.

- Flexibility and quickness on format’ changes

- Smooth, accurate and quiet operation

- Simple and user friendly operation

- Rigid and accurate machine

- Quick and easy change of belt conveyors

FEATURES

- Outputs up to 2.000 bags/hour depending on palletizing formats and number of layers

- Bag’s conditioning system and turning device according to the product, type of bag and required output.

- Counterweighed elevation platform, driven by motor-gear with frequency inverter

- Layer forming zone equipped of a double slide-gate with a low friction coating made of polyethylene (PE-1000)

- Side and frontal forming dams, motorized and driven by double rack

- Top flattening of each new layer against the sliding gates

- Pallet’s centering device at the elevation platform

- Automatic pallet dispenser, entrance and exit roller conveyors

APPLICATIONS

- Agro-feed: Seeds, cereals, cattle feed, pet-foods, premixes…

- Foodstuff: Flours, semolina, ingredients, milk powder, cocoa powder, sugar…

- Chemical & Petrochemical: Fertilizers, PVC, plastic granules…

- Building & mining: Mortars, sepiolite, perlite, salt, glass, frit…

- Recycling: Biomass pellets, Shredded tyres…

OPTIONS

- Carton sheet dispenser on empty and/or full pallet

- Dispensing and stapling of a PE sheet (from a roll), on empty pallet

- Automatic dispenser of an interlayer anti-sliding paper-sheet (from a roll)

- Anti-corrosive versions to handle highly aggressive products

- ATEX versions for installation in Classified Areas

- Version for pallet-less applications

Click here to learn more!

Comments are closed here.