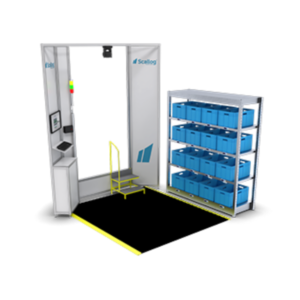

Description

On a mobile frame, the battery, Pick-by-Light displays, scanners, printers and WiFi. The “frame” or Pick by Frame® is coupled to a picking trolley with the entire picking technology and optimally supports the simultaneous picking or sequencing of several orders. After completion of the activity, the frame or Pick by Frame® is disconnected from the car again. LUCA-Server controls the entire process. The Pick-by-Frame is one of the best manual picking systems.

Preparation

The car barcode is captured with the scanner. Depending on the requirements, the items are picked either directly into the car compartments (car motif or production) or in shipping boxes and boxes. The shipping boxes and boxes must be prepared before the picking begins. For boxes, the box barcodes are assigned to the seats and orders on the cart. For shipping cartons, the corresponding carton sizes are assigned to the orders and positioned on the cart. A large cardboard box can also occupy several seats on the car. Depending on the volume, several cartons/boxes can also be assigned to an order. The preparation is carried out as required. It can be done directly at the pick-by frame® or at a separate workstation.

The mechanical coupling

The pick-by-frame® has its own wheels and is coupled to the picking trolley with the help of guide rails. The mechanical connection of the two constructions is usually carried out by an innovative magnetic coupling. The “permanent electromagnets” hold together the pick-by-frame® and the picking cart. The pick-by-frame® is released from the car by pressing a button that neutralizes the permanent electromagnets.

Batch activation

After the mechanical coupling of Pick by Frame ®, only the barcode of the picking cart is read. The open order lines are loaded and the process can be started. The RFID technology can also be used for the automatic identification of the trolley. The LUCA software manages the connections of the Pick by Frame ® to the trolleys and dynamically coordinates the required switching. A job batch on a trolley can also be edited by multiple employees and frames (e.g. multiple layers or zones in the warehouse).

Login of employees

If desired, the system can support employee sign-in. During the feedback, the employee ID can be sent for each picked position. The information is usually evaluated on the HOST system.

Pick by Frame® Process

The picking process is created at LUCA according to the customer’s wishes. The customer-specific requirements are in the foreground here. Basically, the employee is optimally guided through the warehouse and the secure assignment of the items to the orders is optimally supported by the technology.

Scanners are used to secure quality and other data, such as batch, serial number, etc. Various scanners can be used in the Pick by Frame ® process. We have various stationary checkout scanners or mobile hand-back scanners at our disposal. Label printers can also be integrated into the process as required. All details of the equipment and processes are coordinated together with customers and planners and recorded in specifications.

Battery replacement at Pick by Frame

Modern lithium-ion batteries are usually sufficient for one or even several layers. The state of charge is checked directly on the battery. The Pick by Frame ® system is designed so that the battery can be replaced even during operation/order. After re-off, all displays automatically light up again.

Click here to learn more!

Comments are closed here.