Description

Automating and Streamlining DC Interzone Transport

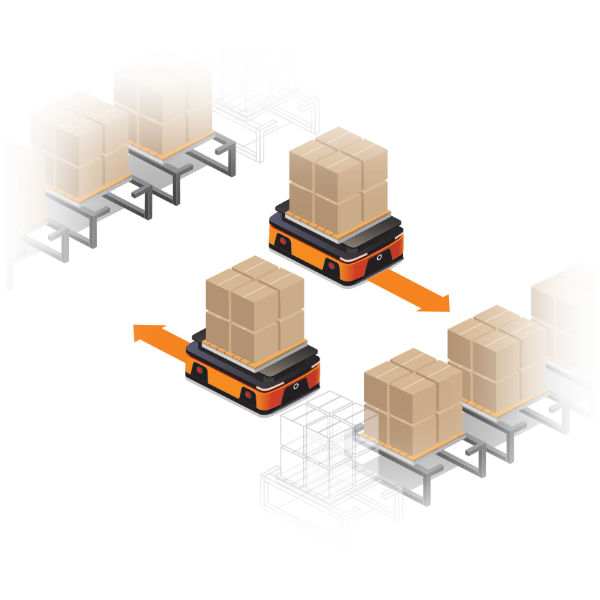

The Ranger IL (Intralogistics) robot is an intelligent, versatile Autonomous Mobile Robot (AMR) engineered to move a diverse range of inventory payloads – on pallets, racks, cages or trolleys – among zones in a warehouse. By automating material transportation, distribution centers can optimize productivity, focus workers on higher-value activities, and schedule deliveries more effectively to reduce material bottlenecks.

Simple, ready-to-run implementation and the ability to adapt workflows in real time to accommodate shifts in delivery volumes or orders enable Ranger IL to generate a rapid return-on-investment through increased productivity, reduced material damage and saved time, cost and labor.

Features

- Rapid, ready-to-run implementation – ready-to-run means Ranger IL delivers near immediate value in time, cost and accuracy.

- Seamless travel across DC interzones – engineered to traverse warehouse inter zones carrying a diverse variety of payloads.

- Flexibility to adapt in real time as orders vary – workflows can be adjusted in real time through dynamic integration with GreyMatter™.

- Mobile spatial navigation reduces accidents – ranger IL operates in accident-free collaboration with other robots, automated infrastructure, people and inventory.

Less time, less labor,

Higher safety for people and materials

GreyMatter intelligence assesses DC performance in real time and orchestrates how and when Ranger IL transports inventory among zones, dynamically adjusting to protect SLAs, avoid bottlenecks, heighten throughput and protect the safety of people and materials.

Ranger IL uses advanced Simultaneous Localization and Mapping (SLAM) navigation along with GreyMatter mobile-spatial intelligence to operate in accident-free collaboration with other robots, automated infrastructure, people and inventory. The robot’s patented vertical motion Lift Deck™ enables it to handle additional forklift tasks and greatly reduce pallet and trolley damage through smooth vertical storing.

Click here to learn more!

Comments are closed here.