Description

HIGH RESOLUTION PRINTING TECHNOLOGY

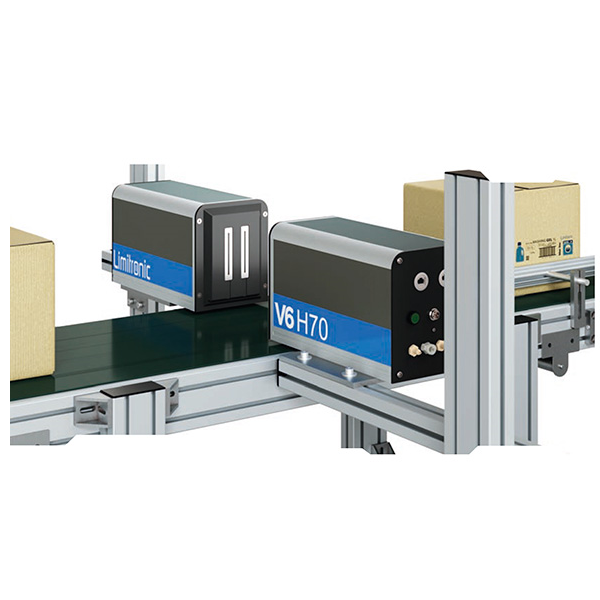

Coding printing equipment V6 Spot Multi-block contains Modular solutions. and an industrial console. The Coding printing equipment V6 Spot Multi-block is manufactured by Limitronic, S.L.

Multiple possibilities for print head blocks with the Coding printing equipment V6 Spot Multi-block. Also customised printing height and an integrated message editor

Printable products

Porous, glossy, coated cardboard, paper, textiles, wood, plastic, metal, foam, EPS…

Features

- Opposite faces

- Different heights

- Different lines (independent)

- Native resolution of 180dpi or 360dpi

- Multiple densities and contrasts

- High quality bar codes. GS-1 standard

- Intuitive user environment

- Actual on-screen preview of the message to be printed (WYSIWYG)

- Oil based and UV LED inks

- External hardware message selection

- Integration with post-print bar code reader

- Scripting for full customisation of jobs

Advantages

- Customisation. Short print runs. Promotions

- Reduction of stock of pre-printed containers

- Practically zero maintenance

- No stoppages to change consumables

- Printing on ramps of any inclination

Options

Encoder, post-printing bar code verification, alarm beacons, bar code reader for selecting products, external message selection.

Print specifications

Print head resolution:

180 dpi

360 dpi

Speed:

60 m/min @ 360dpi

0.2 – 192 m/min depending on the resolution

Height:

70 mm and 140mm per block to 180

and 360dpi

Maximum length: +100 metres

Densities: 3 levels

Font type:

True Type ™, Open Type ™ fonts

Character coding: Unicode

Bar codes:

GS-1 standard

EAN/UPC, ITF-14, GS1-128, GS1 Datamatrix,

GS1 QR Code

Printing of variable fields:

Of user (customised fields) and automatic

fields (expiry dates, shift codes, counters)

Orientation:

Vertical (side of the product)

Horizontal (top of the product)

Click here to learn more!

Comments are closed here.