Description

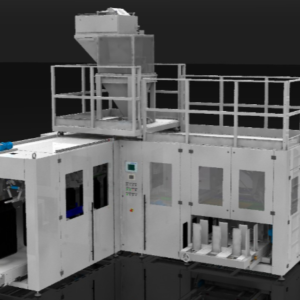

Filling Machine ILERSAC L (automatic) is an automatic bagging machines for open mouth flat-top or side gusseted bags, oval shaped filling spout for powdery products.

BENEFITS

- Total automation of the bagging process

- Flexibility and quickness on format’ changes

- Output optimization at the bagging point

- Absence of remains and possible product contamination

- Maximum accessibility for cleaning and maintenance tasks

- Dust-free working conditions.

FEATURES

- Outputs up to 1.000 bags/hour depending on product’ characteristics and formats to handle

- Open mouth flat-top or side gusseted bags made of paper, PE or laminated PP

- Oval shaped filling spout with external clamp for total obturation

- Bags’ top stretching and extraction set by robotic pincers

- Dust aspiration outlets to connect to the filter. Aspiration piloted at the filling spout

- Double stack of empty bags, automatic change of trays

- Dosing system by means of gravity, belt conveyor or auger screw as per product properties and output requirements

- Gross weight or net weight configurations, depending on output requirements

- Simple and user friendly HMI

APPLICATIONS

- Agro-feed: Seeds, cereals, cattle feed, pet-foods, premixes…

- Foodstuff: Flours, semolina, ingredients, milk powder, cacao powder, sugar…

- Chemical & Petrochemical: Fertilizers, PVC, plastic granules…

- Building & mining: Mortars, sepiolite, perlite, salt, glass, frit…

- Recycling: Biomass pellets, Shredded tyres…

OPTIONS

- Side gusseted bags’ handling system at the bags’ magazine

- High capacity empty bags’ magazine

- Integrated bags’ coding/labeling system

- Double filling spout for multi-format applications, automatic change

- Product settling function through bottom vibration, lateral kick, deaeration rod or mechanical deaeration depending on product properties and type of bag

- Integrated closing systems: heat sealing, stitching, pinch top

- Air extraction before sealing

- Inert gas injection before sealing

- Anti-corrosive versions to handle highly aggressive products

- ATEX versions for installation in Classified Areas

- Manufacturing in Stainless Steel

Click here to learn more!

Comments are closed here.