Description

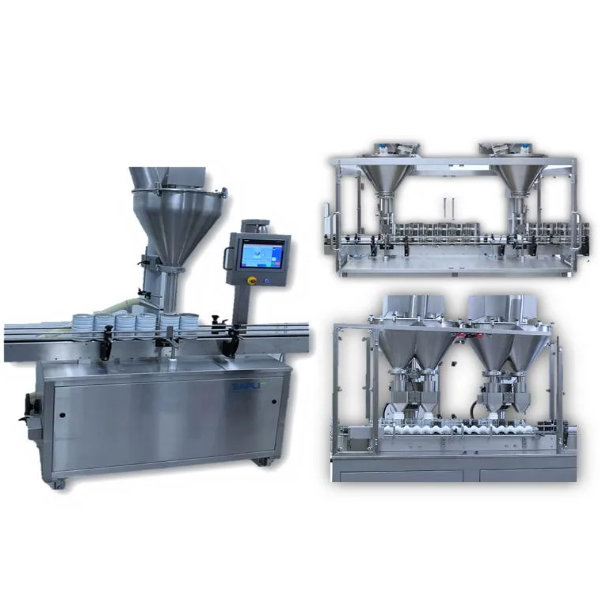

Sapli’s Inline powder filling machine can be configured with Single or Double Filling stations. In case of required higher production rate the 4 filling stations configuration is proposed (two Double Filling stations). The Inline powder filling machine includes easy-clean conveyor and stainless steel food-grade product contact parts, vibration at point of fill, lift system for smooth bottom-up filling, no-container no-fill control, no tools changeover, and positive container indexing.

Features

• Auger with servo driving

• Compact and clean machine design

• Intuitive user-friendly interface

• High precision auger machined from solid

• Food grade stainless-steel parts in contact with the product

• Format change without use of tools

• eWON VPN Router for Sapli remote technical support

• No bottle – no fill safety system Hopper coupling, self-aligning, quick disconnect

• Automatic base cabinet

The filler is able to fill with a high precision a wide range of products and volumes. The filling capacity is from 50ml to 2000 ml for each station.

Volumetric or Gravimetric filling principle can be applied depending on the product requirements.

Depending on the density and chemical features of the product optional lifting and vibrating operation can be added in order to fill the product in the most optimal way.

The optional aspiration nozzle on the mouth of the filling station extracts possible dust in case of very free-flowing product with small particles, allowing minimizing the contamination of the filling chamber.

Bottom-up filling option allows compacting in the best way the product, guarantying the best fitting of the product into the container.

The format change is easy and intuitive consisting in adjustment of containers guide rails, head position and indexing of cylinders. No tool is required for the change of hoppers, funnels and auger, in case of need.

Click here to learn more!

Comments are closed here.